Our Infrastructure

Koyas Fasteners has the state-of-the-art, manufacturing plant with a production capacity of more than 4,000 metric tones per annum.

Product Realisation Processes including Raw Material annealing, Phosphating and drawing are carried out in-house. Integrated Quality Management System is well established in the plant.

Raw materials are procured from only reputed sources in "As Rolled Condition" which is accepted after thorough in-coming inspection. Accepted materials are passed for wire processing and each coil is assigned a unique number for the purpose of identification and traceability.

Cold Forging

After the wire rod is converted into the desired size the same is loaded into the cold forging machine for making Industrial Fasteners like Bolts, Studs, Screws, Nut, Special Fasteners etc

Wire Processing

Wire rod is thoroughly cleaned in HCL. After pickling, wire rod is rinsed in running water in tank and then it is subjected to water rinsing, thereafter it is heated up in hot water bath. Then the absolutely cleaned steel coil is phosphate coated and rinsed. It is finally dipped in Bond lube bath and thereby soap coating is applied on phosphate coating

Wire Drawing

Wire rod is thoroughly cleaned in HCL. After pickling, wire rod is rinsed in running water in tank and then it is subjected to water rinsing, thereafter it is heated up in hot water bath. Then the absolutely cleaned steel coil is phosphate coated and rinsed. It is finally dipped in Bond lube bath and thereby soap coating is applied on phosphate coating.

Annealing

Annealing is carried out for cold formation of metal to take care of critical shapes. The entire annealing cycle in terms of temperature and time is critically controlled.

Bolt Forging

There are 7 multistation Cold Bolt Formers and Cold Headers of internationally renowned makes are operational in our plant. With the in-house manufacturing Engineers and Design team, KOYAS FASTENERS is strong in producing various types of Fasteners with and without threads for all types of Industrial needs.

Nut Forgings

There are 2 Cold Nut Formers and KOYAS has the capability to forge any type of Cold Forgeable nut of Standard and Special category.

Thread Rolling Facilities

KOYAS Thread Rolling machines comprising of 4 nos. of flat die type machine and 3 rotary die machines. Cold thread rolling ensures more precise and stronger threads than cut threads. For obtaining a better fatigue resistance, threads are rolled after Heat Treatment as is needed in critical automobile engine bolts.

Nut Tapping

KOYAS have 3 nos. of 4 spindle Auto nut tapping machines of the latest high speed technology for tapping nuts with high precision.

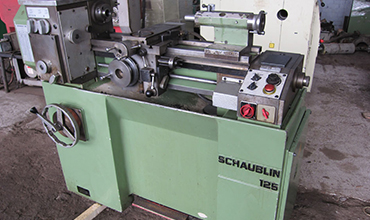

Other Secondary Operation machines

KOYAS have Turning machines, Centreless Grinders, Copy Turning Lathe, Drilling machines, Cylindrical grinders for all special and precision Fasteners.